What Is PDSA?

PDSA stands for plan-do-study-act. PDSA is a basic quality improvement process that allows an organization to test and analyze a change on a small scale to determine whether it is improving a process or making it more efficient.

What Does PDSA Cover?

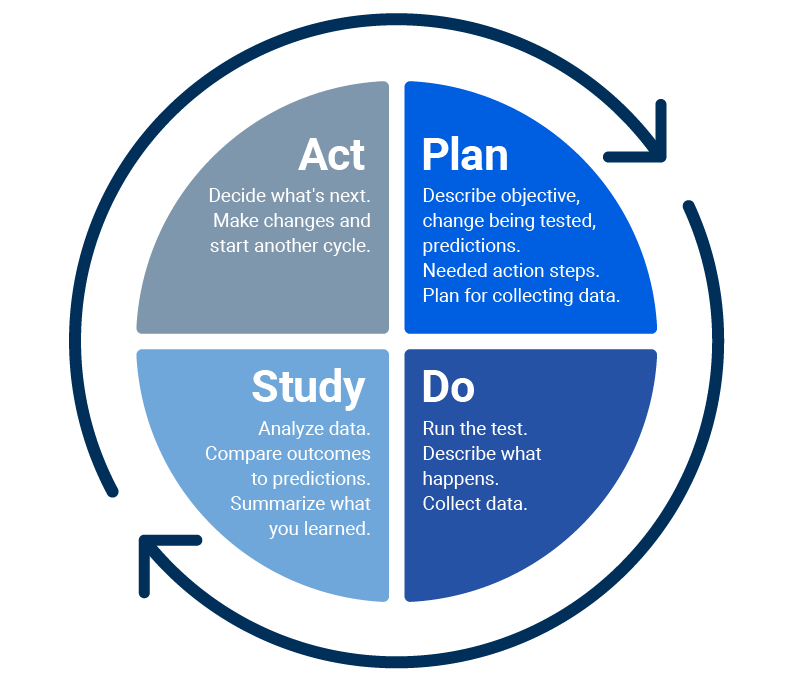

The PDSA framework covers four phases. It allows organizations to plan to test a change in a process (plan), to carry out that test by making changes in that process (do), to observe and analyze, through measurements, the effects of that change (study), and then to decide how to react to that first test (act).

Sometimes, the last phase includes the implementation of a change; more often, it includes further modification of that change and then the repetition of another PDSA process. An older term for the same process is plan, do, check, act, or PDCA.

What Is a PDSA Cycle?

The four steps in plan, do, study, act are often called the PDSA cycle. In many cases, organizations repeat the PDSA cycle many times, as they make slight modifications to the change they’re testing in order to determine how those modifications affect results.

What Is a PDSA Model of Change or a PDSA Change Model?

The PDSA model of change, or PDSA change model, is a general term describing the process improvement theory behind the four phases of PDSA. You produce a desired change by executing the PDSA process or cycle, thus, leading to a “model of change.”

What Is the PDSA Model?

PDSA model is a phrase sometimes used to describe the PDSA process or is an abbreviated way to refer to PDSA model of change.

What Is PDSA Quality Improvement?

PDSA quality improvement is a particular type of QI. The PDSA cycle is often part of a larger quality improvement program. Some of the quality improvement processes are much more complex than PDSA alone. These more complex quality improvement processes include the following:

- Continuous Quality Improvement: This is an overall management philosophy in which organizations do ongoing work to reduce waste, reduce errors, and increase efficiencies in their processes. Learn more about continuous quality improvement at “Where Data Serves People: Benefits of the Continuous Quality Improvement Approach.”

- Lean: This is a quality improvement process that defines value based on what the customer (or, in healthcare, the patient) wants. The model focuses on reducing activities that don’t add value, making tasks more mistake-proof, and constantly reducing waste in a process. Learn more about Lean project management at “The Definitive Guide to Lean Project Management.”

- Six Sigma: Originating in the U.S. manufacturing industry, this quality improvement model works to improve efficiency by minimizing variability in a process and then finding and correcting errors. Learn more about Six Sigma by reading “Six Sigma for Beginners.”

- Total Quality Management: This process focuses on quality improvement that is ingrained in an organization’s culture and management system. Learn more about total quality management at “A Quality Principle: Everything You Need to Know about Total Quality Management.”

- Quality Improvement Collaboratives: Most often used in healthcare, these are processes in which multiple organizations work together to improve a healthcare process in order to improve care for patients.

How PDSA Can Be Helpful in Testing Potential Changes in a Process

PDSA is effective for helping organizations understand and test their processes. PDSA also helps organizations understand how changes might improve their processes. Leaders and employees might consider using PDSA for the following:

- To confirm their hypothesis that a specific change will result in an improvement

- To test which of several possible or proposed changes will best lead to the desired improvement

- To determine how much improvement a specific change might produce

- To evaluate whether a proposed change will work in a real-world environment

- To evaluate whether a combination of changes might improve a process

- To decide which combinations of changes will have the desired effects on the important measures of quality

- To evaluate the costs of a proposed change, along with how it might impact employees, customers, and other processes

- To help lower employee or other types of resistance when an organization implements a change

Types of Changes or Processes That Are Most Ripe for PDSA Analysis

Organizations can use PDSA on almost any process to see how a change might improve the process.

Heather Larivee, an expert in continuous quality improvement and PDSA and the CEO of Sparkflo, LLC., a business consultancy, says she considers PDSA useful when leaders are analyzing almost any process or issue within their organization: “I really think it’s valuable all the time, even when you’re just exploring an idea. ‘Should we do this? Is it even feasible?’”

Still, PDSA can be especially helpful for certain types of processes or changes — sometimes called “promising changes.” Those changes include the following:

- Eliminating Waste: You can analyze any activity your organization performs or resource your organization uses to ensure it adds value.

- Understanding and Optimizing Inventory: Understanding how and where inventory exists within your organization, and how it moves, can uncover opportunities to reduce waste and save money.

- Improving Workflow: You can ensure that work flows as efficiently and effectively as possible in an organizational process.

- Managing Time: You can analyze the time it takes for your organization to accomplish certain tasks and how to shorten those time cycles.

- Reducing Unnecessary Variation: Reducing variation in many processes makes results more predictable and reduces errors.

- Redesigning Systems to Reduce Errors: You can analyze and redesign your systems, so they are less susceptible to human error.

- Improving the Work Environment: Improving the work environment for employees can improve performance throughout your organization.

The First Questions You Should Ask as You Embark on PDSA Work

The PDSA Model for Improvement was developed by a quality improvement organization called Associates in Process Improvement. Associates in Process Improvement was founded by William Edwards Deming, a pioneer of quality improvement processes who worked with the Japanese manufacturing industry after World War II.

The Model of Improvement asks the following three foundational questions in conjunction with the plan, do, study, act cycle:

- What are we trying to accomplish?

- How will we know that change is an improvement?

- What change can we make that will result in improvement?

Primary Steps in the PDSA Process, Including Details Within Each Step

Here are the four primary steps of the PDSA process, along with the tasks and details relating to each step:

- Plan:

- Describe what you want to accomplish in an aim statement or a project charter, or both.

- Describe the current process, the issues with that process, and the overall context.

- Recruit PDSA team members who fully understand the process you’re modifying.

- Identify possible causes of the problem.

- Identify possible changes or alternatives that might fix the problem or improve the process.

- Make predictions about what will happen with proposed changes and why.

- Plan the test of the change, including a plan for what data you will collect and how you will collect it.

- Implement SMART goals (specific, measurable, attainable, relevant, and timely) for the test. Learn more about writing SMART goals here.

- Determine what resources you will need.

- Determine the action steps for the test, along with the people responsible for each step.

- Determine the timeline for the PDSA cycle (i.e., how long the change will take to implement and analyze).

- Remember that you may need multi-generational project planning, which refers to repeating PDSA cycles back to back as you make small modifications to the changes based on the changes that result from each cycle.

- Do:

- Describe in writing what happens when you run the test.

- Collect data that you identified during the planning stage. Your team might find it helpful to use a check sheet, flowchart, swim lane map, or run chart to capture data/occurrences as they happen over time. You may want to use tools like a check sheet, swim lane map, Pareto chart, flow-chart, or run chart to help you collect and analyze the data. Document your observations and any problems and unexpected results you encounter.

- Study:

- Compare the data you’ve collected to the data you acquired prior to the change. Then, compare your most recent data to your predictions.

- Determine if the change resulted in the expected outcome.

- Decide on any lessons learned regarding how you implemented or how you could improve the change.

- Summarize in writing what you learned, including unexpected results, successes, and failures.

- Act: Based on what you learned from the test, your organization should do the following:

- Adapt: Modify the changes and repeat the PDSA cycle, including preparing a plan for the next test.

- Adopt: Implement the changes in the small-scale area where you first tested and then consider expanding to other departments.

- Abandon: Change your approach entirely and repeat the PDSA cycle.

Larivee with Sparkflo says she thinks a more appropriate term for the last part of PDSA is “adjust” rather than “act.” That’s because in most cases an organization is going to finish the cycle by slightly adjusting the changes and then restarting the cycle to determine if those changes will improve results. “The cycle never ends until you reach the point where you say, ‘OK, the experiment has proved out. We’ve now determined the current best way for this process to operate,’” she says. “Or, organization leaders may decide to abandon the changes and work at the problem from a completely different perspective. Either way, that ‘act’ step happens only after many PDSA cycles.”

Tips for Executing PDSA Effectively

Executing PDSA poorly will not only be a waste of time; it could cause you to make changes — based on faulty results — that make your process less effective and efficient than when you started. That’s why understanding PDSA and executing it appropriately are so important. Here are some tips from experts:

- Think about the Process: Analyze, with employee leaders who will be part of the PDSA team, what the PDSA work on a specific business process might look like.

- Ensure Diverse Participation: Ensure that your team includes people who are familiar with all aspects of a process. Doing this often means that your team will be composed of people from different departments within your organization.

- Write Down a Tentative Plan: Create a simple document that covers how you plan to analyze the process and tackle the work, and have team members read and discuss it.

- Create a Project Charter: A project charter is a detailed document that lays out the specifics of the process you plan to study, the members of the team, the basic goals of the project, and the scope of work. The scope of work will provide parameters on what team members will focus on and hope to accomplish.

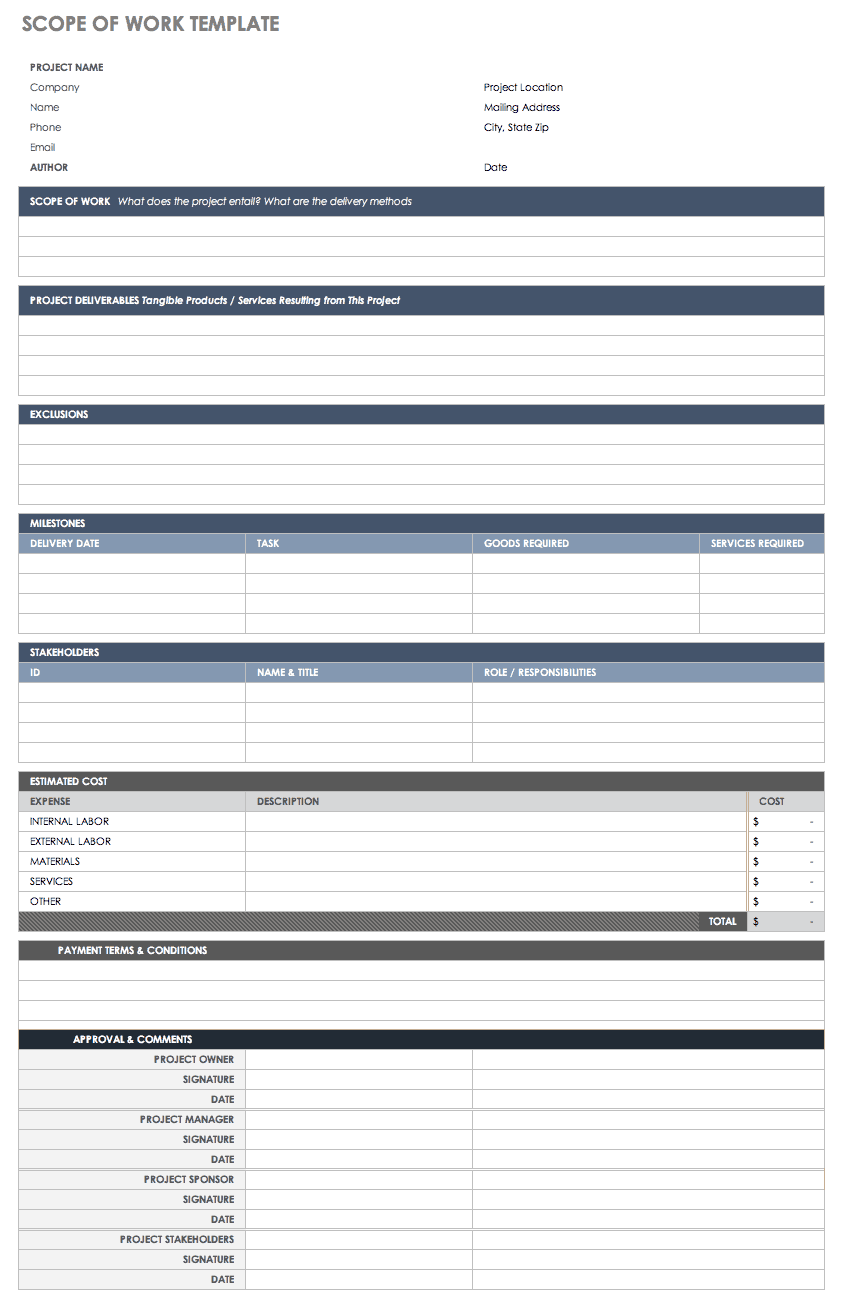

You can use this template to create a scope of work for your project. It will help you describe important aspects of the project, including project deliverables, individual and department responsibilities for those deliverables, timelines, and estimated costs.

Download Scope of Work Template

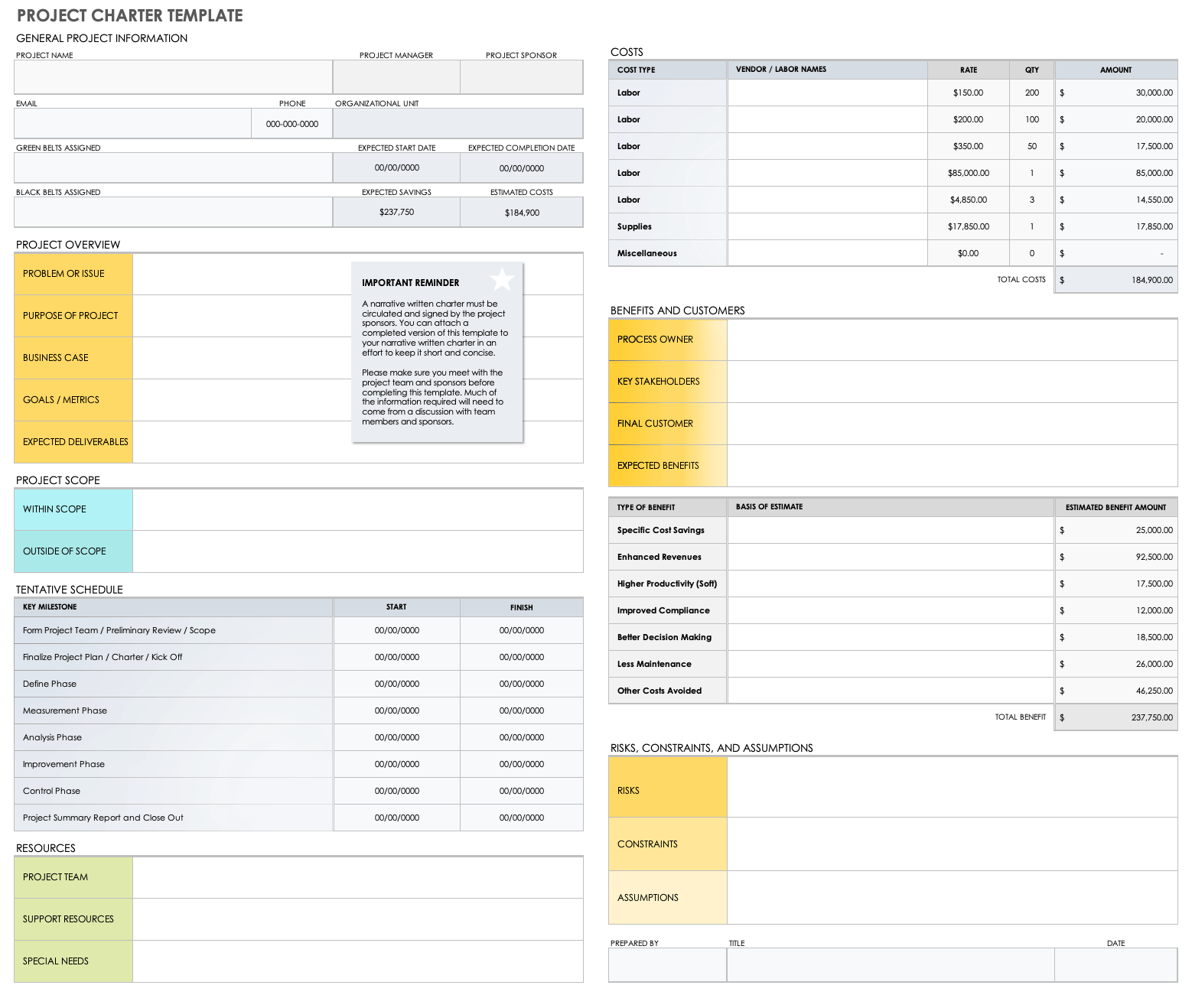

Chuck Cox, a principal consultant with Austin-based Firefly Consulting, says creating a project charter for every PDSA project is vital. “It will not save time if you skip the formal project charter step,” he says. “It will increase the time, effort, and frustration of all the people involved.”

The project charter will help your team set up the appropriate structure for your project and ensure that the team can accomplish what it hopes to, Cox says.

You can use this template to create a project charter for your team. A project charter provides an overview of a project, including team roles and responsibilities, financial information, goals, and constraints. Creating a detailed project charter will help define your project and its expected outcome and will provide a high-level roadmap to follow.

Download Project Charter Template

Excel | Word | Smartsheet

- At First, Work with People Open to the Change: Begin your testing of any proposed change to processes with employees who believe in the change or believe in the possibility of improvement. Don’t concern your team with convincing people to accept the change at this point.

- At First, Go Slowly: Be careful and methodical at the beginning to ensure that the structure of the team, the definition of the problem, and the scope of work are solid.

“Go slow to go fast,” Cox says of beginning a project. “A good project manager knows what the pace should be at every stage of the problem solving, but the most important time in a project is at the very beginning. Establish a structure that will serve your team in an efficient manner throughout your project.” - At First, Think Small: Begin PDSA work on a small scale or with a pilot project. You’ll be better equipped to tackle and become more comfortable with the process; if you start on a small scale, you’ll also be able to understand more clearly how to gather and analyze the data.

- Think Short: You should strive for short PDSA cycles in order to allow your team to gain knowledge about whether the changes are having an effect. Implementing shorter cycles also allows the team to make adjustments if necessary. A PDSA cycle can run for as little as a day or even less. Then, you’ll run another PDSA cycle with what you’ve learned. Your team may run many PDSA cycles within a short time to continually make changes and modify a process. The practice can result in real successes rather quickly.

PDSA is often used as part of quality improvement in the healthcare industry. In “Basics of Quality Improvement in Health Care,” which appeared in the June 2007 edition of Mayo Clinic Proceedings, the authors cite a PDSA example in which providers in an ambulatory medical clinic were trying to improve “medication reconciliation” — the process of creating an accurate list of all the medications that a patient is taking.

In the clinic’s improvement process, each PDSA cycle “lasted 24 hours, with changes made to the medication reconciliation process on the basis of lessons learned from each previous cycle,” the authors write.

By the end of the clinic’s work, after a number of such PDSA cycles, “The average number of discrepancies per patient decreased by more than 50 percent… The physician-documented medication list contained 47.3 percent of patient-reported medications at the start of the study and 92.6 percent by the end of the study. By the end of one month, the clinic had standardized and implemented the new medication reconciliation process.”

Once successful at a small scale, you can expand. When your team has used the PDSA cycles to improve a process on a small scale and analyzed and understood the results, then you can expand to implementation on a broader scale. - Use Analysis Tools: Fishbone diagrams, Pareto charts, and similar tools can help your team visualize and analyze the results.

- Implement When You’re Confident: Implement your idea — the change in the process — only after you’ve considered and tested all the other reasonable options to make the same change.

Examples of Changes Tested by PDSA Cycles

Because the four stages of PDSA are similar to the traditional scientific experimental method, PDSA concepts are often familiar to professionals in the healthcare industry.

Here is a simple example of how the basics of PDSA play out in one specific process:

- Process: A doctor visits to help with blood sugar management for diabetes patients.

- Plan: The doctor agrees to ask one diabetes patient if the patient would like to have a special doctor’s visit to learn how to better manage blood sugar.

- Do: The doctor asks his first patient the question during a regular patient visit.

- Study: The patient indicates interest. The doctor is happy with the response.

- Act: The doctor plans to ask several other patients the question in the same way and to set up visits for the patients who are interested.

Following are two examples of using repeated PDSA cycles to improve a process, including using specific questions to answer during the planning stage:

Example of Changes Tested by PDSA Cycles: Disseminating and Encouraging the Completion of Patient Surveys

This example of changes tested by PDSA cycles concerns disseminating and encouraging the completion of patient surveys. This example includes three PDSA cycles.

- Process (First Cycle): This process seeks to disseminate and encourage the completion of patient surveys. Here is the first cycle of this PDSA:

- Plan: We plan to test a process of distributing and encouraging patients to complete clinic satisfaction surveys:

- Goals: We are seeking the completion of 25 surveys in one week.

- Steps:

- We will display the surveys at the patient checkout desk.

- The desk attendant will encourage patients to complete the survey and place it in the box on the desk.

- We will conduct the test for one week.

- Do: We document our observations:

- Patients are often attending to other things at this time and do not want to take on another task.

- Sometimes, the checkout area is busy, with people waiting.

- Nevertheless, the attendant often asks patients to complete the survey.

- Study: What did we learn?

- Answer: Only eight patients had completed surveys by the end of the week. The process was not effective.

- Act: We document our conclusions:

- The patients did not want to complete the survey once the doctor was finished.

- We must find a way to get patients to complete the survey when they have time.

- We will encourage them to complete the survey at home and will provide them with a stamped envelope to return the survey.

- Plan: We plan to test a process of distributing and encouraging patients to complete clinic satisfaction surveys:

- Process (Second Cycle): This process seeks to disseminate and encourage the completion of patient surveys. Here is the second cycle of this PDSA:

- Plan: We plan to test a process of distributing and encouraging patients to complete clinic satisfaction surveys:

- Goals: We are seeking the completion of 25 surveys in one week.

- Steps:

- We will display the surveys at the patient checkout desk.

- The desk attendant will encourage patients to take the survey and an envelope with them when they leave, complete the survey at home, and mail it to us.

- We will conduct the test for two weeks.

- Do: We document our observations:

- The desk attendant tells patients about the survey request during the checkout procedure.

- Patients have other papers to deal with at checkout.

- Approximately three in 10 patients take the survey and an envelope with them when they leave.

- Study: What did we learn?

- Answer: Only three patients had completed and returned surveys by the end of two weeks. The process was not effective.

- Act: We document our conclusions:

- Patients did not want to be bothered with additional tasks at checkout.

- When patients left the clinic, they were unlikely to remember or complete the survey.

- We must approach patients at a different point in their visit, possibly when they’re waiting for the doctor.

- Plan: We plan to test a process of distributing and encouraging patients to complete clinic satisfaction surveys:

- Process (Third Cycle): This process seeks to disseminate and encourage the completion of patient surveys. Here is the third cycle of this PDSA:

- Plan: We plan to test a process of distributing and encouraging patients to complete clinic satisfaction surveys:

- Goals: We are seeking the completion of 25 surveys in one week.

- Steps:

- We will leave the surveys (with pens/pencils) in the exam room.

- We will ask the nurse to do the following after they’ve taken each patient’s vital signs: mention the survey and ask patients to complete it while waiting for the doctor.

- We will conduct the test for one week.

- Do: We document our observations:

- The nurse tells patients about the survey.

- Some patients need help reading the survey; the nurse is not able to help because they are too busy.

- Periodically, the doctor enters the room while a patient is working on the survey. Therefore, the patient does not complete the survey.

- Study: What did we learn?

- Answer: Patients had completed 24 surveys by the end of one week. The process was more effective.

- Act: We document our conclusions:

- It was more effective to ask patients to complete the survey while they were still at the clinic.

- Most patients had time to complete the survey while they were waiting for the doctor.

- We must determine how to assist people who may need help reading the survey.

- Plan: We plan to test a process of distributing and encouraging patients to complete clinic satisfaction surveys:

Example of Changes Tested by PDSA Cycles: Getting Doctors to Perform Teach-Back with Patients

This example of changes tested by PDSA cycles concerns motivating doctors to perform teach-back with patients. Like the last example, this one also includes three PDSA cycles.

- Process (First Cycle): This process seeks to motivate doctors to perform teach-back with their patients. Here is the first cycle of this PDSA:

- Plan: We plan to ask doctors to perform teach-back with the last patient they see on Wednesdays. Teach-back is the act of having patients repeat back the instructions that the doctor gives them in order to make sure they understand:

- Goals: We are trying to motivate doctors to perform teach-back with patients more often. We are hoping physicians will find the process useful.

- Steps: We will ask five doctors who hold clinic on Wednesday afternoons to perform teach-back with their last patient of the day.

- We will show these doctors teach-back video.

- We will check with the doctors at the end of the process to see whether they found it useful, or too time consuming, and whether they would do it again.

- Do: We document our observations:

- The doctors find the teach-back video helpful and seem interested in doing teach-back.

- Study: What did we learn?

- Answer: Four of the five doctors had done teach-back with at least one patient. One doctor had said she didn’t know how to integrate a teach-back into a patient visit.

- Act: We document our conclusions:

- Four of the five doctors felt comfortable with teach-back and said they would continue using it.

- We will look for other teach-back resources to help the fifth doctor understand how to integrate the process into a patient visit.

- We are ready to introduce the teach-back process to the entire clinical staff.

- Plan: We plan to ask doctors to perform teach-back with the last patient they see on Wednesdays. Teach-back is the act of having patients repeat back the instructions that the doctor gives them in order to make sure they understand:

- Process (Second Cycle): The five doctors will perform teach-back with their patients. Here is the second cycle of this PDSA:

- Plan: We plan to ask five doctors (after they finish clinic on Wednesday) the number of patients with whom they performed teach-back that day.

- Steps: We will check with the doctors at the end of the process to see whether they found it useful or too time consuming, and whether they would do it again.

- Do: We document our observations:

- Some of the doctors cannot find the appropriate time or circumstance in which to perform patient teach-back. Still, all feel it is a worthy practice that they should remember and do more often.

- Study: What did we learn?

- Answer: Three of the five doctors had performed teach-back with three patients. One had performed it with one patient. One hadn’t performed it at all. (The non-performer in this cycle was the same non-participant as in the first cycle.)

- Act: We document our conclusions:

- Some of the doctors were using teach-back and some weren’t.

- We realize that the goal of involving teach-back in half of all patient encounters might be unrealistic.

- We may place a sign in clinic rooms to remind doctors about teach-back.

- We will measure frequency again in six months.

- Plan: We plan to ask five doctors (after they finish clinic on Wednesday) the number of patients with whom they performed teach-back that day.

- Process (Third Cycle): The five doctors will perform teach-back with their patients. Here is the third cycle of this PDSA:

- Plan: We plan to put signs saying "Teach It Back" in exam rooms in order to remind doctors to perform this exercise.

- Steps:

- We will ask doctors if the signs reminded them to perform teach-back.

- We will see if teach-back increased in Wednesday afternoon clinics.

- Steps:

- Do: We document our observations:

- Nurses feel that the signs impede clinical care.

- Study: What did we learn?

- Answer: Four of the five doctors had each done teach-back with three patients on Wednesday afternoon. One had done teach-back with one patient.

- Four of the five doctors said that seeing one of the signs was a reminder to do teach-back.

- Act: We document our conclusions:

- The doctors needed a reminder to prompt them to use the tool during patient visits.

- We will not pursue further intervention.

- Plan: We plan to put signs saying "Teach It Back" in exam rooms in order to remind doctors to perform this exercise.

Template for using PDSA in a Business Process

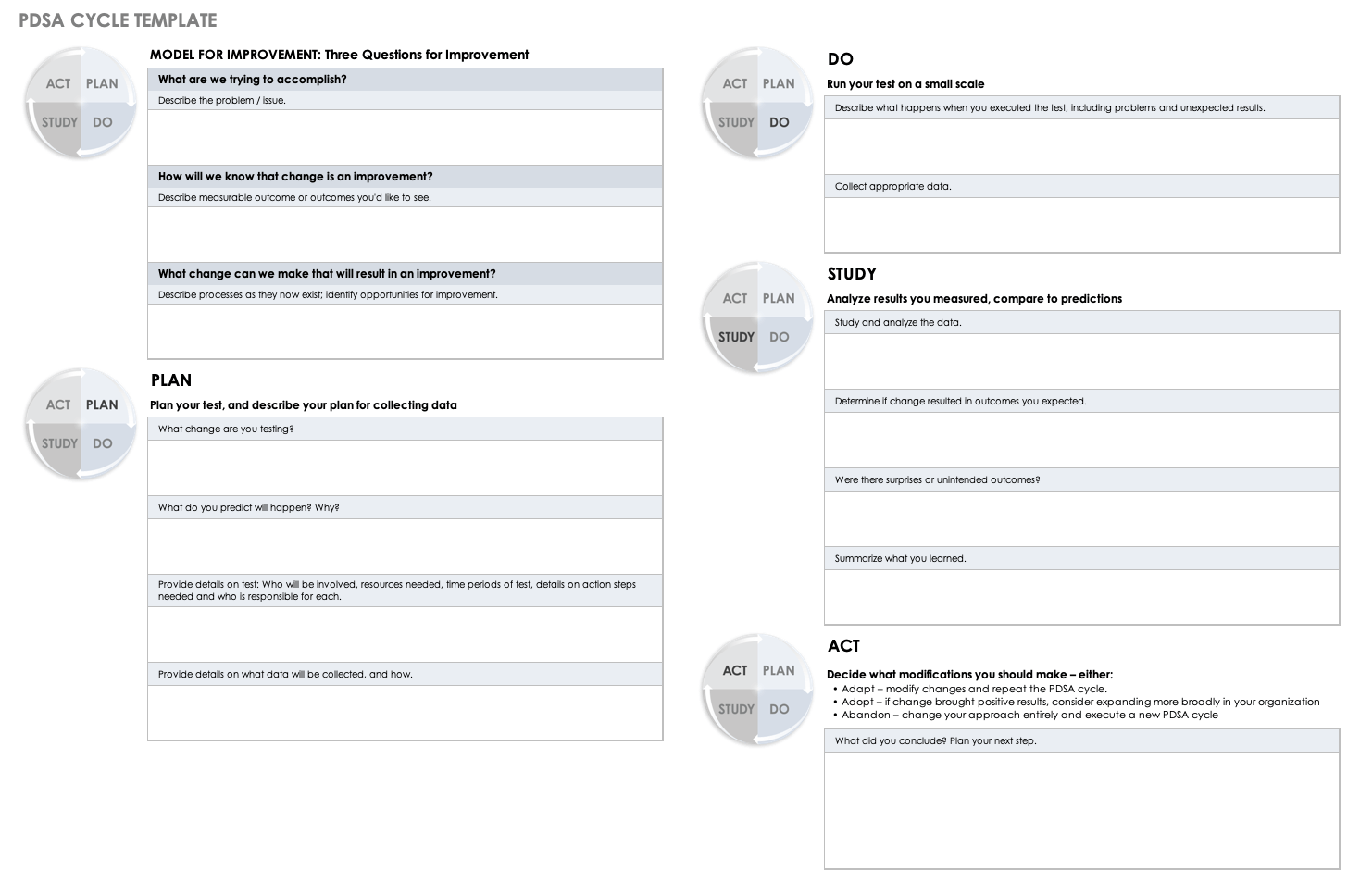

You can use this template to assess important PDSA questions that you want to ask in order to improve a business process. You can also use it to help you answer significant questions as you move through the PDSA cycle. You can download this template for free and customize it to fit your needs.

Download PDSA Cycle Template

PDSA in Nursing

Nurses have long been a part of quality improvement in healthcare. Because PDSA is a basic part of quality improvement, nurses have also been integral to PDSA cycles in healthcare.

Their position at the forefront of PDSA and quality improvement relates in large part to the traditional role of nurses in healthcare. They are routinely in the best position — 24 hours a day, seven days a week — to see how healthcare institutions deliver care to patients. Because of their central role in the healthcare system, they are especially able to recommend — and help test — changes that might improve treatment.

Benefits of a Well-Executed PDSA

When an organization executes a PDSA cycle (or repeated PDSA cycles) properly, the exercise can be remarkably effective at helping an organization determine the best changes to make in order to improve a process. Here are some of the benefits of PDSA when you execute it properly:

- It enables the testing of changes on a small scale, which allows you to build and improve on test cycles before implementation on a broader scale.

This quality can help in analyzing different types of changes to a process. PDSA is particularly useful “if you want to explore what happens when you pursue one option versus another option,” Sparkflo’s Larivee says.

That small-scale analysis can also help an organization “avoid and detect pitfalls and unintended consequences,” Larivee says. “It gives you the opportunity to make changes further upstream versus waiting until a project is complete and then finding out all of the problems you have to fix once the project is done.” - It allows organization leaders and staff to better understand organizational processes.

Cox, with Firefly Consulting, says PDSA is helpful “when trying to solve a problem that involves a process that is not very well understood. This describes just about every circumstance in which a problem has to be solved.” - It is efficient, often not requiring excessive resources.

Cox says PDSA can be especially useful “when you don’t have huge sums of money to throw at a problem. When there are a limited amount of funds and/or resources and no tolerance for waste regarding reaching a viable solution, PDSA is both efficient and effective.” - It can sometimes help organizations save significant money by improving processes.

- It improves consistency, which almost always means improving quality.

- It can help an organization adapt more easily to future external changes that will impact its processes.

Cox says PDSA work not only improves an organization’s process, but also provides an organization’s leaders and employees with new knowledge about that process. If an organization’s employees have done their work properly, that knowledge will help them continue to improve a process as they’re monitoring it. It will also help them continue to improve a process as inevitable internal and external factors affect it in the future.

“The environment surrounding any process is dynamic,” Cox says. “When the environment changes — and it will — will you have generated enough knowledge of the process to be able to change it in order to take advantage of the new environment? The goal is not just to survive external change, but to thrive on it, to leverage it for greater advantage.” - It can help make a process more sustainable.

Organizations that go through multiple PDSA cycles in order to analyze a process understand that process better and understand the fixes that will be the most efficient and effective in the long run, says Larivee. “PDSA will go a long way toward ensuring that a process is sustainable,” she says. - It teaches an organization’s employees a problem-solving process that they can use over and over again.

“By implementing PDSA, you give people the opportunity to learn about a new problem-solving framework that they may not have been exposed to. You cannot put a price on that,” Larivee says.

Hurdles to the Successful Execution of PDSA and the Biggest Mistakes Organizations Make

There are many common mistakes that organizations make (and many hurdles that organizations create) when trying to execute PDSA. These issues can render the PDSA ineffective or even impair the process an organization is trying to improve. The following are the most common mistakes and hurdles:

- Not Establishing the Appropriate Scope of Work to Understand and Test: Firefly’s Cox says that organizations frequently establish a scope of work to analyze and test that’s too broad. If an organization can’t finish the PDSA work and get usable results within six months, the scope of work is too broad, he emphasizes. Leaders must narrow the scope to something that staff members can accomplish within six months; after that, a team can perform other PDSA cycles on other parts of a problem. Many PDSA cycles are much shorter than six months.

- Not Establishing a Formal Project Charter Every Time: Leaders often bypass this step with the misperception that they’re going to avoid wasted time and effort.

- Not Giving Enough Attention to the “Plan” Stage:

Charles Freeman is a business consultant and community college professor with expertise in Lean, PDSA, and other continuous quality improvement methods. He says that organizations often rush into assuming they know the answer to improving a process; as a result, they don’t give enough attention to the “plan” stage before moving on to the “do” stage, wherein they’ll test their hypothesis.

I always “define measurements, analyze, and thoroughly scope out the context of what I’m trying to achieve. Then, I look at the situation from multiple angles — all before I start the implementation phase,” Freeman points out. “On a percentage basis, the ‘plan’ should occupy the largest amount of time you spend on the whole cycle. Most people spend the least amount of time on the planning. And, doing that will set you up for failure.” (See Freeman’s video on the history of PDSA here.)

Larivee says that some organizations just want to get to the doing stage. “But, if we don’t know what we’re doing, we’re probably not going to get good results,” she says. “There’s a strong drive simply to jump in when you don’t fully understand the problem or its causes. When there’s no plan, you don’t know what to measure. Therefore, you have no way of knowing whether the things you’re doing are even working.” - Alternatively, Getting Stuck in the Planning Stage: Some organizations spend too much time pondering, too much time in the planning stage. “We can sit around for days, months, or years in the planning stage and never move past that,” she says.

“Yes, we want to plan, but we also want to understand how the plan is working,” she says. “So, we have to do it. We have to do what we said we were going to do.” - Not Exploring or Using the Right Measurements to Gauge Success: “I think especially with improving technology, we have a lot more data available at our fingertips,” Larivee says. “But, not all data is applicable, so it might not inform our PDSA.”

- Allowing Biases or Presumptions to Skew an Evaluation: Freeman says that it’s vital for organizations to use the right metrics and measurements and to honestly evaluate what the results are showing. “You have this preset notion that something is the right solution,” he says of a change that an organization might be testing. “Coming in with that presumption can bias the study phase. You need to look at a change realistically. Did it truly solve” the problems in a process?

- Not Creating Written Records of the Work: You must document your work to better understand the process and help make the changes necessary for another PDSA cycle.

- Not Including Enough Feedback Opportunities During a PDSA Cycle: It is crucial to create sufficient feedback opportunities during a PDSA cycle or immediately following a short PDSA cycle. “You must provide the maximum amount of feedback opportunities to allow your team members to make any necessary mid-course corrections as they uncover new information,” Cox says.

- Not Understanding How to Adapt PDSA to Address Different Problems: You must be able to adapt PDSA to address different problems in different stages of every quality improvement project.

- Thinking That PDSA Is Only for Small-Scale Tests: You can also use it for large and broad processes.

- Overestimating the Short-Term Payoff: Some organizations assume the savings or the return on investment (ROI) for a QI or PDSA will come immediately. Instead, they should be calculating the savings and ROI using life cycle costing, which assesses cost savings over a much longer term. Organizations are too often “driven by instantaneous costing,” Cox says. “That causes you to make some bad decisions.”

- Pursuing Changes That Don’t Align with Your Organization’s Overall Business Strategy: “No organization has the resources to pursue every problem,” Cox says. “So, use the organization’s (overall business) strategy to guide which projects get worked on and which ones don’t.”

PDSA Hurdles and Mistakes in the Healthcare Industry

Quality improvement and PDSA work have real value in the healthcare industry, and industry professionals use these techniques frequently. Here are some of the most common mistakes people make when implementing QI and PDSA:

- PDSA training overestimates the simplicity of the method and underestimates how organizations can use and adapt it for a wide range of complex issues.

- In efforts to quickly train staff members to do the work, managers sometimes omit (and employees sometimes don’t follow) important principles of the process. In practice, these mistakes translate to the following:

- In a healthcare culture that expects quick action, teams move too quickly from “plan” to “do” in the PDSA cycle.

- Healthcare PDSA teams also spend too much time on “do,” failing to move on to the “study” phase.

Details on the American College of Physicians ACP Advance Program

The American College of Physicians (ACP) has created a comprehensive quality improvement program that includes PDSA information and training for healthcare providers. The program espouses four main precepts for achieving effective quality improvement:

- Clinician engagement and ownership

- Team-based care

- Patient and family partnerships

- Maximum efficiency with minimal burden

The program includes the following resources:

- ACP’s quality improvement curriculum

- Physician-led coaching for quality improvement

- Chronic care programs and resources

Research on PDSA Use in the Healthcare Industry

Experts have performed research regarding the efficacy of PDSA, and quality improvement in general, in the healthcare industry. Here are some of the findings of that research:

- A 2013 article entitled “Systematic Review of the Application of the Plan–Do–Study–Act Method to Improve Quality in Healthcare,” in the journal BMJ Quality & Safety, found that “From the articles that reported details of PDSA cycles, it was possible to ascertain that variation is inherent not just in reporting standards, but in the conduct of the method, implying that the key principles of the PDSA method are frequently not followed.”

- The same article suggested that although healthcare organizations are increasingly using quality improvement practices, “The evidence base for their effectiveness is poor.” About PDSA, the article found that “PDSA cycles are often a central component of QI initiatives. However, few formal objective evaluations of their effectiveness or application have been carried out.”

- A 2004 article entitled “Guidelines for Appraisal and Publication of PDSA Quality Improvement,” in the journal Quality Management in Health Care, said that answering the following four primary questions can determine the value of a quality improvement study:

- Is the quality improvement study pertinent and relevant?

- Are the results valid?

- Are you using the appropriate criteria to interpret the results?

- Will the study help a healthcare entity with its practice or organization of care?

Research on How PDSA Worked in a Specific Process: Increasing the Effectiveness of Colon Cancer Screenings

A 2017 article entitled “Applying the Plan-Do-Study-Act (PDSA) Approach to a Large Pragmatic Study Involving Safety Net Clinics,” in the journal BMC Health Services Research, analyzed how PDSA worked in an effort to improve a study that was testing the effectiveness of a cancer screening program. The screening program involved the mailing of fecal immunochemical tests to patients of health centers in Oregon and California.

The article found that PDSA work refined the study’s staffing methods, improved the study’s outreach materials, and changed the workflow steps in the study’s mailing program.

Use PDSA to Improve Your Processes with Real-Time Work Management in Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.